INTAKE AND PRE-CLEANING

Mixer MO 1, 2, 3, 4

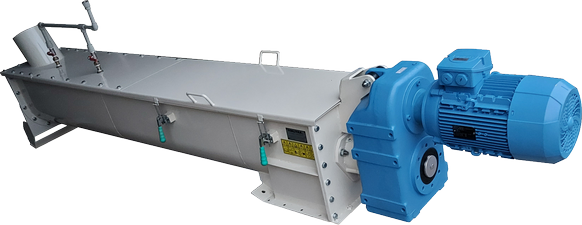

The mixers is used for dampening of superficial layer of grain kernels prior to milling. This way higher flexibility and toughness of the skin is reached and its crushing to flour reduced. A high speed rotor with a relieved worm spiral and spreaders thoroughly stirs up the grain and water mixture to allow better water penetration into the skin layers of kernels

Benefits

- Rovnoměrné zvlhčení slupky zrna projevující se vyšší výtěžností kvalitních mouk

- Minimální poškození procházejícího zrna

- Spolehlivý provoz nevyžadující stálou obsluhu

- Vysoká životnost

Description of the machine

The rotor is mounted to roller contact bearings by clamps. It is made of a steel tube with welded-on stainless steel worm spiral at its inlet end. The other part is furnished with steel rod replaceable spreaders. The rotor lower end is sealed by a special stuffing box. The machine body is made of stainless steel with a top removable cover and two interconnected water supply cock sat its inlet to accept hoses 1/2". The trough extreme bottom has got a draining cock. The machines are driven by electric motors . The outlet end is provided with a choke up probe to stop the machine drive and the entire preceding machinery in the line when necessary.

Technical data

| Type | Worm diameter (mm) | Power input (kW) | Output (t.h-1) | Weight (kg) | |

| netto | brutto | ||||

| MO 1 | 320 | 5,5 | 5-10 | 459 | 530 |

MO 2 | 320 | 7,5 | 10-15 | 491 | 570 |

MO 3 | 400 | 7,5 | 15-20 | 565 | 650 |

MO 4 | 400 | 11 | 20-25 | 625 | 720 |

Files for download:

Gallery