INTAKE AND PRE-CLEANING

Pre-cleaning separator type PSVT(R) 50

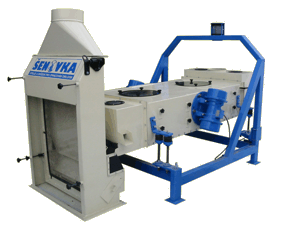

Pre-cleaning separator type PSVT50 is used for cleaning and grading of dry and gravity flowing materials by means of a set of sieves (small and coarse admixtures) and cleaning in an air stream in an aspiration case (dust and liftings). The machine works with a closed circuit of cleaning air and limited air exchange from the machine outside. These machines are usable mainly in pre-cleaning sections of flour mills but they are suitable also for other processes where grainy materials should be cleaned, graded and cleaned from fine and coarse admixtures.

Benefits

- Low electric power consumption

- Closed cleaning air circuit

- Simple replacement of sieves

- Separation of three kinds of screenings of different bulk weight and size

- Reliable operation without permanent attendance necessary

- Easy visual checking of the machine operation

- Simple adjustment - screen inclination, throw angle (set angle of vibromotors), oscillation amplitude and circulating aspiration of air sifting intensity within the air sifter can be easily set to the user’s request

Description of the machine

The Pre-cleaning Screen Separator is a machine consisting of the Screen Separator PSVT 50 and the Air Sifter AS 7 with aspiration air recirculation and built-in magnet separator to remove ferromagnetic objects.

The Screen Separator PSVT 50 consists of a frame and a straightly vibrating screen suspended in the frame with inlet and outlet chambers. In the screen there are sieves clothed with perforated sheet (upper sieve) and wire cloth or, for special applications, with full sheet (bottom sieve). The screen oscillation is excited by two attachment vibration exciters.

The Air Sifter AS 7 is a machine working with an enclosed air circuit. Its inlet end is connected directly to the screen separator. It consists of a magnet plate, aspiration chamber with control means for the air sifting intensity control, separating chamber with a worm discharger and an air lock, a built-in fan with air channel and grain outlet with a packing counterweighted flap.

Technical data

| Output | 30-60 t.h-1 (according type of material) | |

| Drivers | Screen separator | 2 x 0,55 kW - vibrators |

| Air sifter with recirculate | 4 kW – air sifter fan | |

| 0,55 kW – worm and air lock | ||

| Volume of aspiration air | 10 m3.min-1 | |

| Recirculating air renewal | max. 10% | |

| Weight netto | 1070 kg | |

| Weight brutto | 1600 kg | |

| Built-up space | 11 m3 | |

| Upper sieve (A) | Perforated sheet metal | Ø10 mm, Ø12 mm, Ø15 mm |

| Lower sieve (C | Wire cloth | 1,8 x 1,8 mm, 2x2 mm, 2,24 x 2,24 mm |

| Basic placing | ||

| síto A | Perforated sheet metal | Ø15 mm |

| síto C | Wire cloth | 2 x 2 mm |

Throat | Ø219 mm | |

Net product outflow | 200 x 998 mm | |

Spill of small impurities (sand) | Ø152 mm | |

Spills of coarse impurities | 2 x Ø219 mm | |

| Spills dust and airborne impurities | Ø152 mm | |

Aspiration throat on aspiration cabinet | Ø100 mm | |

Files for download:

Gallery