INTAKE AND PRE-CLEANING

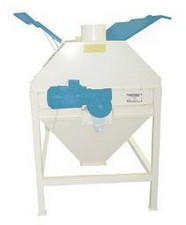

Drum sorting machine BT

It is used to clean and sort the cereals mainly into two fractions. The main functional part of the machine is a drum-shaped sieve with a diameter of 800 mm and a total length of 2320 mm. The raw material to be cleaned or sorted with the inlet nozzle is fed into the inner part of the drum where it is separated, depending on the size of the screen, into two or more fractions. Sieve overflows are coarse impurities and impurities from grain. Sieve breakage is a product devoid of coarse impurities and admixtures, such as pre-cleaned grain. Dust particles that are released during the raw material passage through the machine can be efficiently drained by external aspiration. For this purpose, the machine is equipped with an aspiration socket on the drilled parts of the machine.

The length of time the material passes through the machine depends in particular on the inclination of the drum and its speed, and on the number and design of the blades which are located in the inlet part of the drum and along its length. The exhaust from the machine must be connected to a separating and aspiration device that is not part of the machine. The machine is designed for installation in a technological line for processing dry bulk materials.

Benefits

- Reliable operation that does not require permanent operation

- Different variants of separation networks

- Easy efficient control of grain processing performance

- Easy maintenance

Description of the machine

Three-sided castings are welded from steel profiles and sheets. The sorting drum consists of a shaft provided along a total of 3 pieces of 800 mm diameter rings.

The first ring in the inlet is provided with blades for easier and faster delivery of material into the drum's functional space.

In a further part of the drum, L-shaped blades are arranged between the individual rings to assist in more efficient cleaning and axial movement of the cleaned product.

The screens can be replaced by folding the top covers of the machine. The hinged cover is divided into two sections on each side of the machine and allows easy inspection and maintenance of the machine.

Cleaning brush brushes are placed in the bar longitudinally in the tilt of the drum and help to clean the screen

during rotation of the drum.

Depending on the raw materials and requirements, a gearbox with different speeds can be used, or the drum speed can be varied to a certain extent, for example by means of a frequency inverter (not a standard part of the delivery).

Technical data

| Type | Input (kW) | Output parameters | Weight | |||

| ( m3 / hour ) | ||||||

| BT 800 | 1,5 - 3 kW | 4-30 | 480 kg | |||

Files for download:

Gallery