INTAKE AND PRE-CLEANING

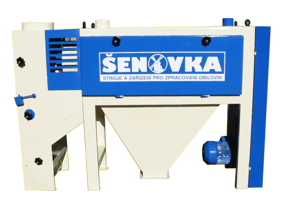

Scouring machine OS

It is used especially in grain mill plants, for intensive surface cleaning of cereals from earthy dust, for partial removal of grease, germ and plow. It also serves to finely clean the grain surface after standing (before milling).

Upon entering the machine, the corn is pushed against the sieve by the blades of the rotor and advances by the working cylinder to the drop. The cleaning is effected by friction of the beater, sieve, and grain friction between each other. The loose impurities in part pass through the sieve into a waste outlet and are partly carried by air aspiration or pneumatic transport outside the machine.

Přednosti:

- Reliable operation that does not require permanent operation

- Improves the purity of the flour produced

- Easy installation

Popis stroje

The cabinet and frame of the machine are made of metal structural elements. On the sides of the cabinet are the door for mounting and dismantling the mesh. At the top is an inlet throat and a throat for connecting the aspiration.

The rotor forms a cylinder with a shaft. On the circumference of the cylinder are the blades with blades. The rotor is dynamically balanced. The screen has a cylindrical shape. It is longitudinally divided into two parts.

The electric motor is located on the inlet side at the bottom of the machine stand. Power transmission is V-belts. Machines included in the mechanical transport lines are completed with an aspiration cabinet. The cabinet is connected to the outflow side so that it is part of the machine. The cabinet is equipped with control elements for optimal function adjustment. The aspiration channel is covered by a transparent wall that allows visual adjustment adjustment. At the top there is a throat for connecting additional aspiration.

Technical data

| Parameter | Unit | Type | |||

| OS3 | OS7 | OS10 | OS15 | ||

| Output | t/h | 2 – 4 | 4,7 | 10 – 12 | 12 - 15 |

| Driver | kW | 4 | 7,5 | 11 | 15 |

| Air volume | m3/min | 10 – 20 | 15 – 25 | 20 – 30 | 40 - 50 |

Pressure loss | Pa | 100 – 150 | 100 – 150 | 100 – 150 | 100 – 150 |

| Weight netto | kg | 582 | 612 | 612 | 943 |

| Weight brutto | kg | 810 | 840 | 840 | 1170 |

| Built - up space | m3 | 2,1 | 2,1 | 2,1 | 6 |

Recommended ventilation equipment for OS types

| OS3 | OS7 | OS10 | |

Separator | Horizontal OH 600 | Horizontal OH 600 | Horizontal OH 600 |

Sealing device | TU 200 (0,55 kW) | TU 200 (0,55 kW) | TU 200 (0,55 kW) |

| Ventilator | VN 400 (2,2 kW) | VN 400 (2,2 kW) | VN 400 (2,2 kW) |

| Separator | Ø 475 | Ø 630 | Ø 630 |

| Sealing device | TU 250 (0,55 kW) | TU 250 (0,55 kW) | TU 250 (0,55 kW) |

Mechanical transport in individual aspiration

Files for download:

Gallery