INTAKE AND PRE-CLEANING

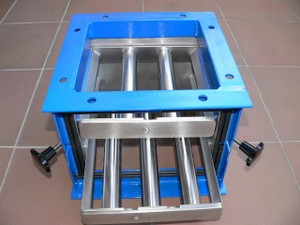

Magnet separator MD 01

Plate permanent magnet separators are used for removal of ferromagnetic admixtures from grain, gravity flowing feed formulations or grainy materials. Application for other materials should be tested in advance and consulted with the manufacturer.

Benefits

- Easy installation

- Reliable operation that does not require permanent operation

- Easy operation and installation

- possibility to assemble magnets into cascades

Description of the machine

One plate magnet separator module consists of a case with a door and a check window. Inside the case there is a magnetic block fitted to a tilting plate and a wiper. The metal case with inlet and outlet flanges can be fitted with various hoppers. The magnetic block is assembled of prismatic magnet elements with pole extenders.

The plate magnet separator is designed in modular system to allow multiple assemblies for higher throughputs.

Technical data

Magnetic properties (at 20 ° C) - with temperature resistance up to 80 ° C

Number of fingers | Remanence (Br) | Coercivity (Hcb) | Inside coercivity (Hcj) | Max. energy product (BH max) | ||||

| mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | |

| 2 | 1080-1150 | 10.8-11.5 | 796-860 | 10.0-10.8 | >=955 | >=12.0 | 223-247 | 28-31 |

| 3 | 1130-1170 | 11.3-11.7 | 844-884 | 10.6-11.1 | >=955 | >=12.0 | 247-263 | 31-33 |

| 4 | 1170-1210 | 11.7-12.1 | 876-915 | 11.0-11.5 | >=955 | >=12.0 | 263-286 | 33-36 |

| 5 | 1200-1280 | 12.0-12.8 | 876-915 | 11.0-11.5 | >=955 | >=12.0 | 286-302 | 36-38 |

| 6 | 1260-1320 | 12.6-13.2 | 876-969 | 11.0-12.2 | >=955 | >=12.0 | 302-318 | 38-40 |

| 7 | 1300-1350 | 13.0-13.5 | 876-969 | 11.0-12.2 | >=955 | >=12.0 | 318-334 | 40-42 |

| 8 | 1320-1380 | 13.2-13.8 | 876-969 | 11.0-12.2 | >=876 | >=11.0 | 334-358 | 42-45 |

| 9 | 1360-1410 | 13.6-14.1 | 876-969 | 11.0-12.2 | >=876 | >=11.0 | 358-382 | 45-48 |

| 10 | 1380-1450 | 13.8-14.5 | 876-969 | 11.0-12.2 | >=876 | >=11.0 | 382-398 | 48-50 |

Magnetic induction of applied magnets is 13,500 Gauss.

Permanent magnets do not lose magnetic induction, so there is no need to measure or otherwise control them. In case of mechanical damage, an immediate replacement of the damaged component is required. We recommend regular visual inspection during cleaning.

The flow rate in the pipeline must be in the range of 1 to 2 m.s-1. The layer of material passing through the magnetic block must not be larger than 40 mm.

Files for download:

Gallery